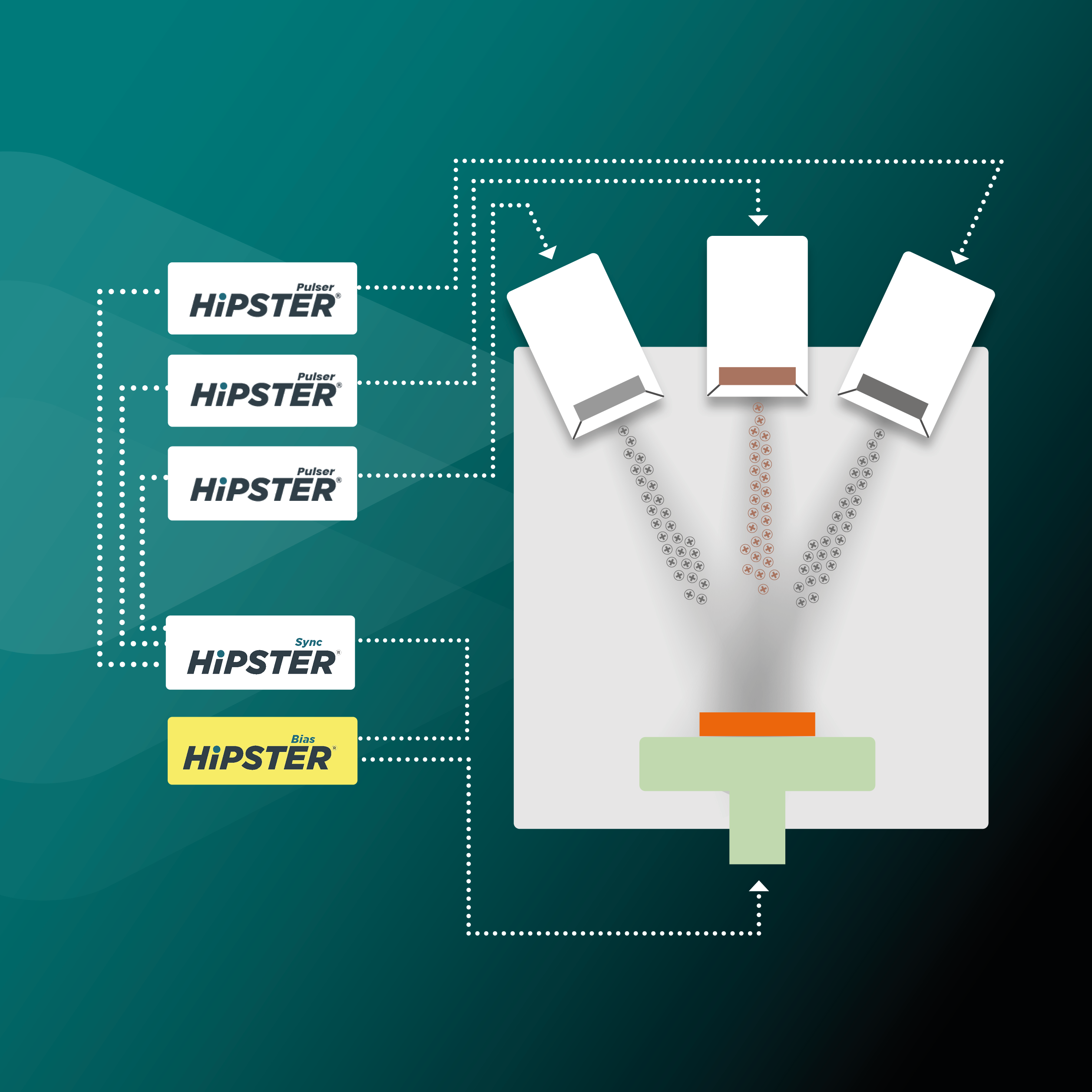

HiPSTER Bias

The key to successful substrate biasing is to use a bias unit that can withstand the high ion flux to the substrate generated by the HiPIMS discharge and thereby maintain the desired bias voltage. Advantages of using our HiPSTER Bias solution is achieved by synchronizing the substrate bias to only the metal-ion-rich portion during the HiPIMS pulse. This is typically realized by slightly delaying the pulsed bias to suppress inert gas-ion bombardment in favor of predominantly metal-ions. The pulsed bias signal must be synchronized to the HiPIMS pulse using our HiPSTER Sync Unit.

FEATURES

- Pulsed bias operation for total control of ion acceleration to the substrate

- Easy synchronization to one, or several, HiPIMS discharges with maintained bias voltage throughout the entire pulse

- Wide bias voltage range that also allows substrate plasma etching prior to deposition

- The possibility to separate metal ion- from gas ion-induced effects allows for low-temperature growth of single-phase metastable alloys with larger grain size, strong preferred orientation, high hardness, and low stress

APPLICATIONS

- Hard coatings: Smoother and denser elemental as well as reactively deposited compound coatings, which result in increased hardness, reduced corrosion, and less friction

- Optical coatings: Increased optical properties through smoother interfaces and denser structures

- Diffusion barriers: Better performance through increased coating density

- Electrical coatings: Improved conductivity enabling reduced coating thickness and reduced heat load. Also increased isolation in the case of insulators can be obtained

- 3-D coatings: Uniform film coverage on complex shaped substrates

Top-quality products require top-quality components. In order to achieve an optimal result, we recommend using our tailormade HiPSTER DC units and our cables. Contact us for a package deal.

Download data sheet here.